Universal Wellpad

Controller

(UWC)

Bringing innovation to oil and gas industry with edge computing

The Oil and Gas industry that is the lifeline of the global economy requires highly complex and state-of-the-art technology to function smoothly. Improving operational efficiency is paramount considering the global demand for oil and gas industry products. Technology innovation has always been a key focus for this industry and today Edge Computing is revolutionising how this industry operates, enabling faster response times, cost-efficiencies, and minimising downtime risks.

Softdel’s Universal WellPad Controller (UWC) is an innovative offering driving this industry-wide transformation: UWC fuels innovation across the upstream oil and gas industry with its feature-rich middleware edge compute platform (powered by Intel®).

Connect

to various Modbus

devices

Inference and

Prioritise real time data

Exchange

pathways for process control, SCADA, and backend data systems

Process

customisation to meet

specific application needs

please share details

to book a demo

Features of

Universal Wellpad Controller

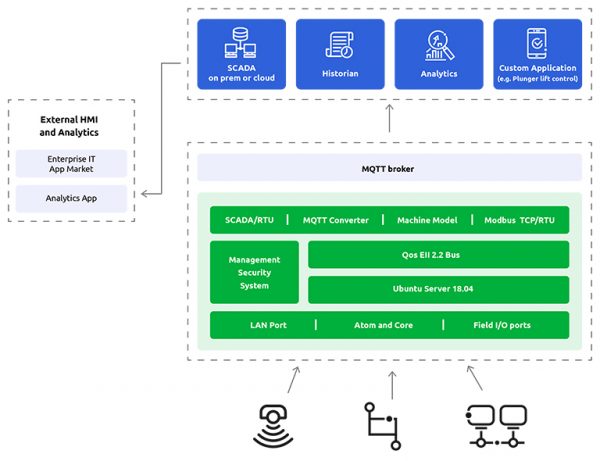

Most systems in the oil and gas industry have an architecture that is characterised by a tight coupling between hardware and software. With microservices architecture at its core, UWC decouples these two components, enabling real-time control for multiple applications.

UWC’s platform has two very distinctive features, extensibility, and edge analytics, that allows operators and integrators the ability to perform near-real-time analysis of data at manufacturing sites for driving better efficiency and process optimisation.

SCADA (Supervisory Control and Data Acquisition) is at the core of many control systems across the oil and gas industry. A SCADA plugin in the UWC platform helps in efficient integration with all leading SCADA systems and cloud infrastructure.. This key feature enables the UWC to be deployed anywhere with interoperability across almost all third party solutions.

Managing security risks is an essential activity within the upstream oil and gas industry and is a critical component of the UWC platform. Our platform enables seamless updates and upgrades, ensuring maximum system security as you move to modern architecture.

Why Choose the

Universal Wellpad Controller?

Leverage the power of edge computing

Process time-sensitive data from remote locations without latency and utilise the cloud to store historical data

Vendor lock-in prevention

UWC represents the industry-wide migration from traditional proprietary Remote Terminal Units (RTUs) to loosely coupled architecture with multi-vendor interoperability

Aggregation ability

No need for a confusing array of functions. Now, club multiple control functions into one device – the UWC

Easy scaling

UWC was designed to be scalable and flexible, allowing changes to be made without having to modify the middleware framework

Technical

Specifications

| CPU | Available on Intel® Atom/Core/Xeon processor family |

|---|---|

| Design | Robust DIN-rail Fanless Embedded System with Intel® Atom® /Core® Processor with 4 COM, 2 LANs, DIO and RTC |

| Connectivity Support and Data Models | Modbus TCP, RTU |

| Storage | 1 x DDR3L-1333/1600 SO-DIMM, up to 8GB |

| Certifications | ATEX, C1D2 |

Featured

Solutions

The UWC’s flexible platform allows companies to build AI and ML solutions that can subsequently solve complex problems involving artificial lift control. The SCADA RTU microservice interfaces with the SCADA Head end and runs various applications at a lower priority, unless attention is needed. This allows prioritisation of computing resources.

Devices can securely add or update microservices from the cloud or an on-premises-based interface without any changes to the UWC framework. The UWC also supports condition-based monitoring of well components, sending health and telemetry data to the cloud and SCADA.

Get the Universal Wellpad Control brochure